Research focused on new food safety guidance for produce

by June 11, 2024 8:27 am 57 views

Federal regulations require producers and packers to keep their produce packing areas clean and sanitary but don’t offer specific guidelines on how to do it. An Arkansas food science professor is hoping to change that dynamic.

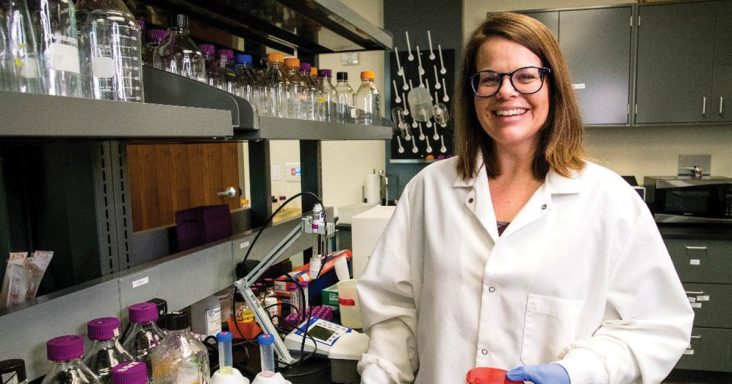

Professor Kristen Gibson told Talk Business & Politics that farmers typically use many different surfaces to store the produce they grow and some of those surfaces could have pathogens. Gibson hopes to study those surfaces and develop a set of best practices that can be shared with producers.

The Center for Produce Safety has awarded Gibson a $206,108 grant to develop new food safety guidelines. It’s a three-year grant, and research will be conducted in several states including Arkansas, Florida and Michigan, she said. The research component is slated to begin in 2025.

Wood, astro turf, carpet, high density foam, and even unusual surfaces used by farmers including mop heads will be studied. Farmers are innovative in their approaches to storing produce, but there needs to be more research into what bacteria are living on surfaces.

“There’s a lot of pathogens we need to be worried about. Bacteria love moisture,” she said.

Hepatitis A, E.coli, salmonella, listeria and others are among the common pathogens found on fresh produce. According to the U.S. Department of Agriculture’s Economic Research Service, foodborne illness caused $17.8 billion in economic losses in 2018, the latest year numbers were available.

The industry-supported nonprofit selected Gibson, director of the Arkansas Center for Food Safety and researcher for the Arkansas Agricultural Experiment Station, to identify and address potential gaps in sanitation protocols within produce packinghouses, where recently harvested fruits and vegetables are handled and packed for distribution. The experiment station is the research arm of the University of Arkansas System Division of Agriculture.

Gibson said the research seeks to provide produce growers with best practices for cleaning and sanitizing surfaces in packinghouses.

“A lot of times, we assume that things are safe to eat,” Gibson said. “For consumers, you want to be sure that your growers are using the best practices available based on science.”

The three-year grant will focus on porous food-contact surfaces typical of produce packinghouses, like unfinished wood and vinyl fabric.

“In the produce industry, people are very innovative, and they like to use different surfaces to protect the quality of their produce,” Gibson said.

Recognizing that produce growers use a wide variety of surfaces in the process of packing produce, Gibson said the research will validate cleaning and sanitation processes for common, hard-to-clean, porous food-contact surfaces and develop best practices.

The U.S. Food and Drug Administration’s Produce Safety Rule became effective in 2016, establishing “for the first time, regulatory requirements for on-farm growing, harvesting, packing, and holding of produce.” Gibson said cleaning and sanitizing are major components of the rule, with specific recordkeeping requirements. However, the rule lacks specific protocols that growers must follow.

“There’s not a ton of guidance on cleaning and sanitizing,” she said. “It tells you the steps. You have to clean to get the dirt off the surface, and then you have to rinse, and then you have to sanitize. But it doesn’t tell you how exactly to do that. As a grower, you have to develop your own sanitation protocols, and this can be really hard for some growers.”

This is particularly true for produce packinghouses, where there is a need for more guidance on cleaning and sanitizing porous food-contact surfaces, she said.

“Produce packing houses can be lots of different things,” Gibson said. “It can be a totally enclosed structure with brick and mortar and very environmentally controlled. And it can be a shed where you have an awning and some tables outside.”

Gibson said the potential food safety risk of porous surfaces in these facilities stems from the difficulty of drying them.

“Most microorganisms thrive in higher moisture environments compared to low moisture environments,” Gibson said. “In addition, these surfaces can be difficult to adequately clean and sanitize due to both the porous nature and the potential adverse effects some sanitizers may have on the materials. With all of that said, the actual risk associated with porous surfaces is unknown. For example, although microorganisms may thrive on these surfaces, they may also become trapped and thus not able to transfer to the produce via cross-contamination.”

Gibson’s research team will conduct two phases of research. First, they will interview small to medium-sized growers from around the country to understand how different surfaces are used in the industry.

“Using this approach enables us to have more in-depth discussions with those industry members we are trying to serve,” Gibson said. “We let the overall results of these interviews drive the direction of the research.”

Next, using information gathered during the first phase, the team will evaluate the ability of microorganisms to survive and grow on the most common porous food-contact surfaces subjected to different conditions relevant to produce packing houses. The goal, Gibson said, is to provide data-backed information to produce growers to help them validate their food safety practices.

“This work will correct deficiencies and improve the performance of cleaning and sanitation practices which will be broadly adaptable,” she said. “This work will build a foundation for further exploration of microbial risks associated with specific packing practices.”