NLR recycling plant will supply aluminum products to Toyota

by November 3, 2021 5:53 pm 1,018 views

A newly opened plant in North Little Rock will produce recycled materials that will be used to build new Toyota vehicles.

Officials with Toyota Tsusho America and Alter Trading Company were on hand along with Gov. Asa Hutchinson and local officials Wednesday (Nov. 3) to celebrate the opening of a new Altec Recycling plant. The plant started operating in September and will employ about 25 people at full strength.

The $20 million plant came into existence after the St. Louis-based Alter Trading Company, a scrap metal company, acquired the Arkansas-based Tenenbaum Recycling Group’s eight facilities three-and-a-half years ago. Tenenbaum had been established in 1890.

Altec Recycling is the result of a partnership between Alter and Toyota Tsusho America, a Toyota supply chain manager with 11 other recycling operations in the United States and additional locations in Canada and Mexico.

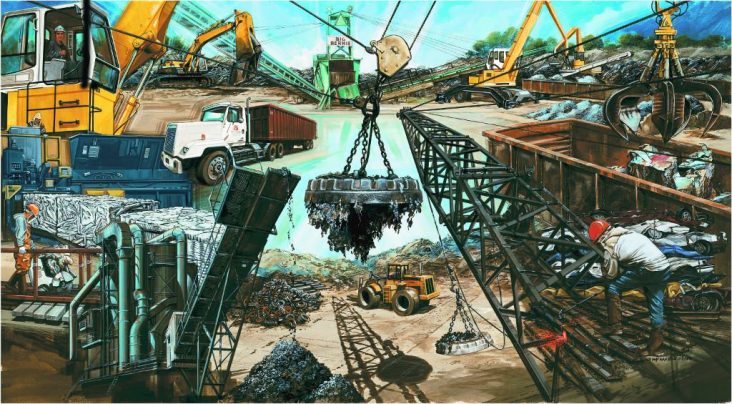

The new plant uses material derived from automobile shredder facilities in North Little Rock and Rogers. Jack Grundfest, Alter Trading Corporation President and the former head of Tenenbaum, said the shredding process produces a stream of materials. Iron is extracted using drum magnets and sold to Nucor and Big River Steel, which have facilities in Northeast Arkansas.

The rest of the stream includes nonferrous (not containing iron) metals that don’t stick to a magnet. The mixture of metals, known as zorba, is transported to this plant, which further separates the lighter aluminum, a product known as twitch.

The twitch will be melted in furnaces in Birmingham, Ala.; Jackson, Tenn.; and Troy, Missouri, into an alloy used for producing transmission housing, engine blocks and automotive parts in Toyota products. Toyota plants in the United States and overseas will use the material.

The process at the North Little Rock plant also produces a mixed heavy metals product including bronze, zinc, copper and other nonferrous metals that is sold overseas.

Hutchinson said the plant opening is part of a larger effort toward Arkansas gaining a greater share of the auto manufacturing industry.

“If you look at the national map as to the supply chain and automobile industry, it all moves our direction, and we have key suppliers here. … This is good for Arkansas because it puts us one step closer to making the case that we ought to have a major manufacturer of automobiles right here in this state,” he said during the ceremony.

Asked by a reporter afterwards about Arkansas’ efforts to land an auto plant, Hutchinson said the state is well positioned by its geography, supply chain and closeness to the market but faces challenges because of the size of its available workforce.

“There’s nothing in the horizon, but we’re always competing for it,” he said.