Milestone noted in expansion of Aerojet Rocketdyne plant in Camden

by March 19, 2020 2:04 pm 2,544 views

A large steel casting bell used to help build large solid rocket motors for the Atlas V rocket has been installed in Aerojet Rocketdyne’s plant in Camden. The bell, relocated from Sacramento, Calif., is part of a new investment in its Camden facility.

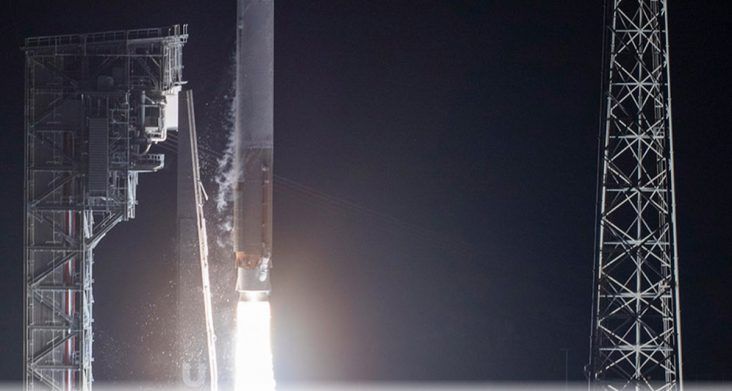

In Camden, the Aerojet Rocketdyne bell will be used to produce large solid rocket motors for programs, including hypersonics and intercontinental ballistic missiles. The Camden facility will be able to produce motors up to 470 inches long and up to 100 inches in diameter. Aerojet is a vendor to Lockheed Martin on the project.

“The installation of the casting bell is a major milestone as Aerojet Rocketdyne continues to prepare for national security programs, including the Air Force’s Ground Based Strategic Deterrent program and the Missile Defense Agency’s Next Generation Interceptor program,” Eileen Drake, Aerojet Rocketdyne CEO and president, said in a statement. “I would especially like to thank state and local leaders from the great State of Arkansas whose efforts have been critical to our ongoing expansion here in Camden.”

The casting bell is a vacuum chamber that eliminates air bubbles that can otherwise form when propellant is poured into solid rocket motor casings, according to Aerojet. The chamber also serves as an oven that heats the propellant during the curing process, and then cools it back down to ambient temperature.

Northrop Grumman selected Aerojet Rocketdyne in 2019 to join its industry team for the Ground Based Strategic Deterrent (GBSD) program, the U.S. Air Force effort to replace the nation’s current Minuteman III strategic missile fleet. Aerojet Rocketdyne would provide a large solid rocket motor system and a post-boost propulsion system for Northrop Grumman’s nationwide GBSD team.