Manufacturers to benefit from COVID-19 relief act, meeting demand for products in wake of pandemic

by March 26, 2020 12:56 pm 2,838 views

The manufacturing industry looks to benefit from a bill aiming to help businesses impacted in the COVID-19 pandemic while manufacturers retool plants to produce products in high demand, such as personal protective equipment (PPE) and ventilators.

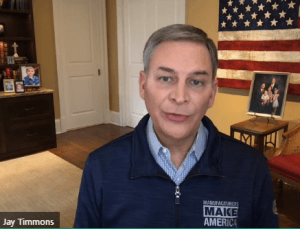

Jay Timmons, president and CEO of the National Association of Manufacturers (NAM), hosted Thursday (March 26) a video press conference to discuss the Coronavirus Aid, Relief and Economic Security (CARES) Act approved by the Senate and the manufacturing industry’s response to and impact as a result of the pandemic.

The bill includes new loan programs to help manufacturers, a new tax credit for employers who continue to pay workers when a business is temporarily forced to close, unemployment benefits for employees working reduced hours, retroactively allows employers to use tax losses to offset income from the previous year, waives penalties for those who withdraw from retirement accounts and provides liability clarifications for respiratory protective devices, Timmons said. It also expands the use of telehealth services and suspends contributions to pension plans for 2020.

“The bill also takes key steps from the NAM plan by increasing the maximum amount of tax deductions for interest on business loans and by creating incentives through loan forgiveness for small manufacturers to retain their employees during this crisis,” Timmons said. “And quite frankly, with 90% of our members being small and medium-sized enterprises, I think that is absolutely the most critical portion of this legislation.”

Timmons said the association will guide manufacturers on applying for the loans from the U.S. Treasury as soon as it receives guidance from federal agencies. The association also will continue to work with legislators on this bill and others that might impact the economy and the country, he said.

In the pandemic, the U.S. manufacturing industry is producing needed healthcare equipment and daily essentials, repurposing facilities and keeping employees and communities safe, he said. NAM is working with federal agencies, legislators and manufacturers to help coordinate the effort and identify supply.

“It’s been said that this is like a war, and it certainly is,” he added. “And in World War II, we all remember that manufacturers were the arsenal of democracy. Today, manufacturers are called on once again but this time to arm our healthcare workers in the battle with this deadly virus. But it goes beyond the front lines of our hospitals. Our grocery stores, they must continue to be stocked. Our electricity needs to keep running. Our devices must keep us connected. Our lives may be socially distant, but life does go on. And that means manufacturers must keep making daily life possible for all Americans.”

Manufacturers have received orders for products that they’ve never made before, and have repurposed facilities to produce products that hospitals and healthcare workers need. Ford, General Motors and General Electric are working together to produce ventilators, Timmons said. Manufacturers are making more respirators and masks. Toyota and Honda are offering their expertise to repurpose manufacturing lines.

State manufacturing associations and partners have worked with government leaders to avoid plant shutdowns in states and keep the food supply chain moving and safe, he said. Recently, NAM asked its members what items they could produce, and more than 1,600 manufacturers responded. NAM is working with the Federal Emergency Management Agency to determine whether the manufacturers can produce those goods, and Timmons said that hundreds could do so. He explained that manufacturers can’t just make masks, for example, but that they must be produced to a specific standard. The association will soon reach out to manufacturers again on this effort.

The association also is coordinating with the federal government on the movement of goods from manufacturers that are willing to donate items.

“One company provided 75,000 gloves, 3,000 Tyvek suits and almost 20,000 facemasks,” Timmons said. “And those were picked up by the government and sent directly to New York City. Another supplied a quarter of a million gowns and a quarter of a million over-the-shoe booties for FEMA to deliver. And another manufacturer had 38 million gloves, and we helped them get through some pretty significant red tape. So those gloves could be flown to FEMA and other critical medical destinations.

“In just a couple of days, we’ve had 116 companies stepping up to provide gloves, 106 offering protective units and 116 with over-the-shoe booties. The response is strong, and it’s growing.”

The association also is working with the Centers for Disease Control and Prevention on how the industry can operate safely during the pandemic. Timmons addressed anecdotal evidence of manufacturers whose production has been impacted because workers don’t feel safe and don’t want to come to work. He noted this is why NAM has asked for specific guidance from the CDC, and he hopes to receive it Thursday and provide it to the manufacturers. The guidance would include proper cleaning protocols, what happens when a worker has COVID-19 and what portions of the facility must be closed in that case. Most of these procedures are already in place at manufacturing facilities but he expects to receive additional guidance from the CDC. The association also is hosting conference calls with thousands of manufacturers to share best practices.

“The very first priority for manufacturers is to make sure that our workers, their families and their communities are safe and healthy,” he said. “Once we can ensure that that occurs, obviously we’re going to continue to ramp up production.”

Asked about the Defense Production Act, Timmons said manufacturers aren’t going to be compelled to do the right thing because they already are, but the act has provisions that might provide for loans or grants for manufacturers that are repurposing their facilities.

Timmons also was asked about the association’s members who have implemented layoffs and reduced production, but he didn’t have data on this, only anecdotal evidence.

“We have heard from many of our manufacturers that they are hanging on as long as they possibly can and keeping their employees on the payroll,” he said. “They don’t want to see that employer/employee relationship severed.” He noted that the CARES act has incentives to maintain that relationship.

Before the COVID-19 pandemic, the U.S. manufacturing industry had 500,000 job openings, but that’s no longer the case today, he said. If the pandemic didn’t happen, he said the number of job openings would have risen to 2.4 million in a few years.

However, if an economic recovery happens quickly, the need to hire employees will rise for those plants that might have shut down during the pandemic or those that need to expand operations. He expects manufacturers will increase hiring quickly, but he doesn’t want another skilled worker shortage. And maintaining the employer/employee relationship is important to the industry.

Amid the pandemic, some manufacturers have increased hiring to meet the demand for healthcare supplies and equipment, he added.

In the United States, 69,684 people have COVID-19, and 1,049 people have died from it, according to data from Johns Hopkins University. Globally, 495,086 people in 175 countries and regions have the virus, and 22,295 people have died from it.