UA civil engineering professor to use soil as building material

by June 25, 2018 12:08 pm 1,767 views

Michelle Bernhardt-Barry, assistant professor of civil engineering at the University of Arkansas, recently received a $500,000 grant from the National Science Foundation to study ways to improve soil, allowing it to be used as a construction material in place of concrete. (photo courtesy the University of Arkansas)

Michelle Bernhardt-Barry, assistant professor of civil engineering at the University of Arkansas, has been studying methods to use soils and sands to build roads and structures in remote areas — or even other worlds — without the access to existing construction materials such as concrete.

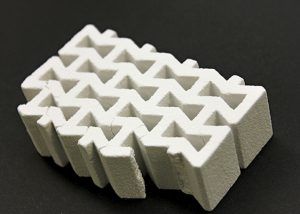

Soil or sand would be the base to create the construction materials using a 3D printer. The printer is needed for consistency as sand comes in various shapes depending on the grain, and angular sand is the strongest. A 3D printer would be used to consistently create the angular sand that’s needed. Also, the printer would create shapes with the sand to improve its strength. One example is a honeycomb shape, and when the materials used to create it are combined into the shape, they become stronger.

Soil was selected as the base material because it’s widely available and could be used in place of concrete to build roads and structures where concrete isn’t readily available, such as in remote places of the world, countries without the resources or even the moon or Mars. Also, soil would be better for the environment than concrete and would reduce the carbon footprint that’s required to produce concrete, Bernhardt-Barry said.

In March, Bernhardt-Barry received a Faculty Early Career Development Program grant for $500,000 from the National Science Foundation (NSF), allowing her to expand her research into soils and sands. This isn’t the first grant she’s received from the National Science Foundation.

“I’ve received other proposal grants, but this one is the largest of its magnitude,” she said. “It’s also the largest in terms of prestige. It’s a pretty competitive grant.”

The five-year grant will allow her to hire two doctorate students to study the methods to produce improved soils for construction materials and to determine their cost-effectiveness and durability compared to existing materials. Bernhardt-Barry will oversee the research and the work of the students. Initially, one doctorate student will work on the project before a second student starts on the project more than two years into it. Graduate student Claire Stewart has been working with her on the project, and previously, former graduate students Matthew

Watters and Behdad Mofarraj worked with her leading up to the grant proposal she submitted to the NSF. Undergraduate students also are expected to work on the project through supplementary funding from the NSF. The grant also will provide for supplies and travel expenses to attend conferences related to the research.

BACTERIA AS GLUE

Bernhardt-Barry has all the necessary equipment for the project, but she plans to apply for a grant for a new 3D printer capable of using sand to print objects. An existing 3D printer allows her to use gypsum. Bernhardt-Barry has used the material, a key component of drywall, to create a synthetic material that is similar to sand, but a downside to the gypsum is it’s not waterproof.

She’s created the material with the 3D printer that binds the gypsum with a proprietary glue. However, she wants to develop a way to bind the materials without having to use the proprietary glue. One option she’s studying is microbial induced calcium carbonate precipitation (MICP), or the use of bacteria to harden soils. The method has been studied for the self-healing of fractures in concrete, and bacteria is used to form calcium carbonate, a key element of limestone. Other options to bind the soils are biopolymers or concrete.

Bernhardt-Barry wants to print the materials using a 3D printer by applying thin layers of soil or sand and using her own method to bind them together. Another print method is to use an extruder, like the tip of a hot glue gun, to dispense a mixture of the soil and glue to bond together.

In the fifth year of the study, the researchers will complete a life-cycle analysis to determine the material’s longevity. It’s one of the final steps to determine whether the material could be commercially viable. And, she hopes to partner with a company to take her product to market. The grant project is expected to run from July 1, 2018, through June 30, 2023.

“I think the trick is figuring out the science part of it and sort of the shapes and the materials and so that it is cost effective,” Bernhardt-Barry said. “That’s going to be the bigger piece. We can build anything, but it’s got to be cost effective.”

CONSTRUCTION USES

Marshall Rucker, a mechanical engineer for Springdale-based Multi-Craft Contractors, said using 3D printers to build structures is limited to the size of the track on which the 3D printer operates, or the reach of its robotic arm. Because of this, 3D printing will likely have more impact on residential construction, rather than commercial construction.

Also, 3D printing of soil as a construction material likely won’t become widely used in construction in the United States unless it’s less expensive than concrete, said Rucker, adding that it would likely be more prevalent in remote areas, which is where Bernhardt-Barry is looking to use this method of construction. As part of her research, Bernhardt-Barry will complete a cost analysis, but the goal is to print soils in those areas that might not have access to other materials such as concrete.

If one were to develop a process to print soils as a building material and ship a 3D printer to an area without a concrete company, Rucker said, the printer could be used to construct homes. And, depending on the skills required to use the printer, the construction method could reduce the number of skilled workers required to build a structure.