Honored Anthony building houses University of Arkansas wood, housing research

by December 17, 2025 2:58 pm 706 views

The $43 million Anthony Timberlands Center for Design and Materials Innovation facility serving the University of Arkansas’ Fay Jones School of Architecture and Design was dedicated Aug. 29.

Architecture students at the award-winning Anthony Timberlands Center for Design and Materials Innovation will research how to use Arkansas’ plentiful wood products in construction, and how to construct affordable housing for workers earning modest incomes.

The $43 million facility serving the University of Arkansas’ Fay Jones School of Architecture and Design was dedicated Aug. 29. Structured and enclosed with wood, it was honored on Dec. 4 by The Architect’s Newspaper, a national news outlet, as its 2025 Project of the Year.

John Ed and Isabel Anthony personally donated $10 million for the building and requested it be named for their family-owned company, Anthony Timberlands. The seventh-generation company is Arkansas’ largest privately owned timberlands and wood products firm.

Dublin, Ireland-based Grafton Architects designed the 44,763-square-foot facility along with the local architect of record, Fayetteville-based modus studio. It was Grafton’s first building completed in the United States. It was modus’s seventh mass timber project, which is a framing style using large wood panels and columns.

Grafton and modus studio were awarded the project in 2020. The design emerged from an open competition process funded with help from U.S. Forest Service grants. A request for proposal attracted 69 submissions, from which six finalists were selected. Modus studio was listed on four of those projects because of its experience with mass timber. Shortly after winning the bid, Grafton won the Pritzker Prize, architecture’s highest honor.

The school has long emphasized the importance of students learning hands-on construction skills. In fact, students are currently working on a full-scale modular home inside the building. Students will use robotics, computer numerical control (CNC) equipment, 3D printing, plasma cutting, and traditional tools to work with wood and metal construction materials.

“We’re seeing, of course, an immense amount of interest in the building because of its design excellence,” said Peter MacKeith, dean of the Fay Jones School of Architecture and Design. “I’m basically functioning as a tour guide now day after day.”

It was modus’ job to interpret Grafton’s competition design and add its own familiarity with Arkansas building standards and cultural design subtleties, said Jason Wright, Assoc. AIA (Associate of the American Institute of Architects), modus studio’s point person on the project.

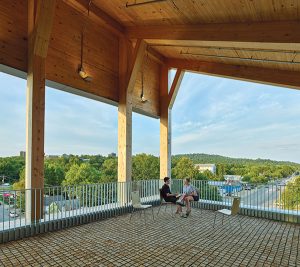

Wright said the building’s cross section emulates the cross section of the Arkansas Ozarks plateau. The roof undulates like Ozark hillsides and valleys. Designers wanted to create an educational facility that would elevate the importance of timber in the built environment.

ACCOMMODATING GROWTH

The school, which next year will celebrate its 80th year, educates 1,100 students with 75 instructors through its departments of architecture, landscape architecture and interior architecture. The renowned Fay Jones was a member of its first graduating class.

The project was meant to accomplish a number of objectives, starting with the simple addition of space. MacKeith said enrollment has grown from 425 when he arrived as dean in 2014 to 1,100 students packed into buildings designed for 500 to 550.

MacKeith said the school also wanted to shift the discussion about architecture and design toward including wood as a structural and building envelope material beyond the scale of a residential house. U.S. Forest Service grants are helping the school explore the use of wood as a building product. The school is also exploring how to use wood dust for construction using 3D printing.

The building demonstrates the use of thermalized wood exterior sheathing, which is not yet a practice in Arkansas. That process prevents wood from rotting or warping by treating it at high temperatures but with low oxygen, so it doesn’t burn. The process breaks down the pathways for water to migrate through the wood, so it doesn’t damage the cell structure. Another unused potential technology the school would like to demonstrate is the use of wood soft panel and hard panel fiber insulation.

RESEARCHING AFFORDABILITY

The school also wanted to engage in applied research applicable to affordable housing, which MacKeith said is a critical need in Northwest Arkansas and across the country.

Students will build demonstration modular prototypes of homes that could be affordable to people earning incomes not far above minimum wage, and that could be expanded on site as the homeowner’s income increases. The homes would be built within local building codes and city zoning ordinances. The school is working with local communities, developers and contractors to put the plans in motion. The goal is to demonstrate how it can be done so developers can be persuaded that the findings are a cost-effective option.

“We’re asking our students to unpack what I’ll call the standard developer pro forma,” MacKeith said. “Which means looking at material costs, construction labor costs, financing costs, design costs, land costs, and then in some ways examining that pro forma in a very — as students can be — very curious way. We are not as interested in what I’ll call market-developing prototypes for market-rate housing as we are in looking at prototypes that are essentially designed to income levels. And for us, at this point, we are exploring housing prototypes that are aimed for people who might make as little as $16 an hour.”

The building is meant to be instructive in its materials, construction, use of natural light and mechanical systems. MacKeith described it as an “encyclopedia of wood” that uses multiple species to their advantage, from the structure to the handrails. Likewise, the mechanical and electrical systems are exposed while complying with building codes so that students can see and understand how the systems are organized.

MacKeith said the visibility added a level of pride in the installation done by tradespeople on the building.

“In this sense, just in the wood and the wood construction alone, we have a building which, as they say, is a member of the faculty,” he said.