UA researchers receive nearly $18 million to build semiconductor fabrication facility

by October 4, 2021 9:13 am 1,561 views

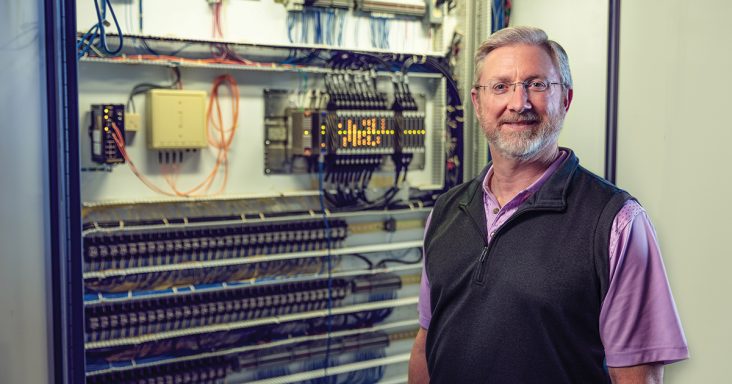

Dr. Alan Mantooth, a distinguished professor in the University of Arkansas' electrical engineering department, said the electric power program's collaborative research has added more than $1 billion to the state's economy.

University of Arkansas engineering researchers led by distinguished professor Alan Mantooth will use a $17.87 million grant from the National Science Foundation (NSF) to build and operate a national silicon carbide research and fabrication facility on campus, according to a Monday (Oct. 4) news release.

“The national impact of having a fabrication facility such as this is enormous,” Mantooth said. “The country that leads the world in advancing silicon carbide semiconductor design and fabrication will also lead the race to market nearly all game-changing technologies, including those used by the military, as well as general electronic devices that are essential to our economy.”

According to the release, the new facility will be the only openly accessible fabrication facility of its kind in the United States, meaning its facilities and services will be available to external researchers. All existing silicon carbide fabrication facilities in the United States are for internal use only, and U.S. research and development of silicon carbide integrated circuits rely on international fabrication. The new UA facility will provide domestic opportunities for prototyping, proof-of-principle demonstrations and device design.

The NSF grant will pay for infrastructure, equipment, technology installation and enhancements to existing facilities to accommodate new equipment. The money also will cover three full-time staff members and a post-doctoral researcher for four years. Other funds are available for set up and operating equipment.

Mantooth and other UA electrical engineering researchers have decades of experience working with silicon carbide, a semiconductor that can withstand extreme-temperature environments. The researchers comprise one of only a few university research groups capable of developing integrated circuits with the semiconductor, the release shows.

The new facility is expected to provide integrated circuits, sensors and devices for military and industrial applications, such as solar inverters, electronics for cars – including electric and gas-powered – and systems used in heavy transportation and construction equipment, such as bulldozers. The electronics developed at the facility also will enable systems used in geothermal and space exploration.

According to the release, the facility will train the next generation of semiconductor researchers and engineers who can work in both the silicon and silicon carbide semiconductor industries.

In an Arkansas Research Alliance webinar earlier this year, Mantooth discussed his vision for the new facility to help companies ramp electronics production. With the five-year NSF grant, his vision is becoming a reality. It will be completed in five phases, he said.

The first phase, which begins soon, will be to purchase the equipment for the facility, Mantooth said. The custom-built equipment can take between six months and a year to receive. Initially, the facility is expected to be in the Engineering Research Center at the Arkansas Research and Technology Park in south Fayetteville.

In three years, he plans to move the fabrication facility into a 15,000-square-foot building. The multi-story building would include a 10,000-square-foot cleanroom that he said would be cleaner than a hospital operating room. The cleanroom is “where the magic happens,” he noted.