Robotics startup hosts successful Kickstarter campaign

by June 2, 2019 4:12 pm 1,039 views

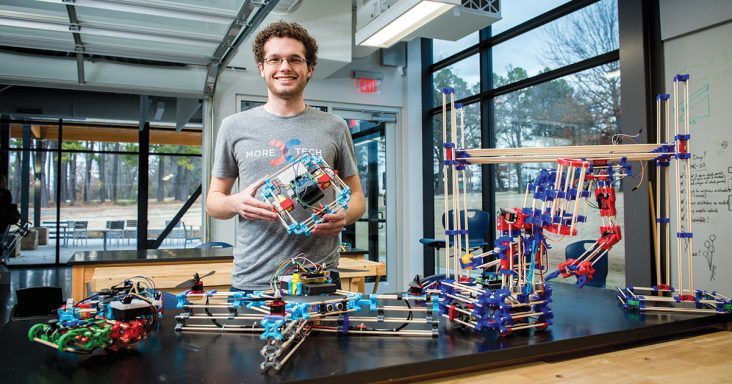

Canon Reeves, CEO of Fayetteville-based robotics startup MORE Technologies, expects to restart production of the company's 3D printed robot in June after completing a crowdfunded Kickstarter campaign in April.

Fayetteville-based robotics startup MORE Technologies recently completed a successful crowdfunded Kickstarter campaign with 161 backers who contributed $21,711 to the company over 40 days.

The campaign, which ended in April, allowed backers to order the company’s 3D printed robot, MOREbot, at a discounted price. Customers can still order the $99 robot, but orders will be fulfilled after those from the campaign are completed.

Searcy native Canon Reeves, CEO of MORE Technologies, said he expects production of the robots ordered in the campaign to start in June and be shipped starting in July. The 21-year-old computer science major at the University of Arkansas co-founded MORE Technologies in April 2018, and within two weeks the company was generating revenue. In a year, revenue has reached nearly $40,000, and it’s built about 200 robots. Key customers are schools, and the robot is geared for students starting from the fifth grade through high school.

Reeves, who expects to graduate in 2021, said his interest in robots has grown since he was 14. He’s started to limit his involvement in other roles to focus more on his company. He co-founded ArkanCode and Lovelace Technologies but is no longer active in those ventures. He was create director for retail technology lab McMillon Innovation Studio at the UA and served as its technical and business mentor. He was also previously the captain of the UA team that competes in NASA’s annual Robotic Mining Competition.

MORE Technologies has four employees and will soon hire an intern. The office — a converted apartment adjacent to the studio — includes a wall of 3D printers and a digital interface for order fulfillment. The majority of the parts for the MOREbot can be purchased at Walmart, such as wooden dowel rods, or produced with a 3D printer. Springdale-based manufacturer Push Plastic provides the plastics, including a plastic with improved heat resistance. Reeves is also developing a 3D printer, offering increased production capacity.