Wolfspeed begins development of fast electric car charger

by September 14, 2017 1:38 pm 1,986 views

The Wolfspeed team in Fayetteville and North Carolina plans to put plenty of speed into an electric car charging device, using wide bandgap semiconductor technology the company has developed over the past three to five years.

Wolfspeed is the power and radio frequency segment of North Carolina-based Cree, a manufacturer of LED lighting and components.

The new device is expected to charge electric vehicle batteries in about four minutes, similar to the amount of time one might spend at a gas station and much faster than some of the fastest electric car chargers on the market, such as the Tesla Supercharger, which requires about 30 minutes for a charge.

“[Silicon carbide] leader Wolfspeed is teaming with U.S. automotive OEM Ford Motor and the University of Michigan-Dearborn to demonstrate an advanced [silicon carbide]-based DC fast-charging system for electric vehicle batteries, with charge times expected to be less than four minutes,” said Jeff Casady, business development and program manager for Wolfspeed. “The proposed system could be a disruptive transformational advance.”

Wolfspeed is a “leading developer of SiC (silicon carbide) power devices, which will offer significant efficiency benefit when doing DC fast charging at these power levels,” said Mike Degner, senior technical leader — electric machine drives for Ford. The feasibility and capability of implementing a DC fast charger based on silicon carbide technology “will help Ford assess the potential for DC fast charging of electric vehicles and the requirements to design vehicles capable of charging at these rates.”

“Ford will provide expertise in automotive systems, electric vehicle charging, requirements and testing,” Degner said.

Overall, it is expected to reduce power losses by more than 60%, be more than 75% smaller, weigh 85% less and cost 40% less than existing electric vehicle fast charging systems, Casady said.

On Aug. 23, the U.S. Department of Energy’s Advanced Research Projects Agency-Energy announced Cree Fayetteville, which operates as Wolfspeed, A Cree Company, will receive $1.91 million to develop a smart, compact, efficient 500 kilowatt DC fast charger for electric vehicles. The funding is part of the Creating Innovative and Reliable Circuits Using Inventive Topologies and Semiconductors (CIRCUITS) program. Casady wrote the proposal for the Wolfspeed project, and it was one of 21 projects that will receive $30 million in funding as part of the CIRCUITS program.

Alex Lostetter, vice president for Wolfspeed, said the company is the lead on the project but is involved as a subcontractor in five of the other projects.

“We were actually on multiple winning teams,” he said.

These projects will implement a new class of efficient, lightweight and reliable power converters using wide bandgap semiconductor technology. The materials used to build them includes silicon carbide or gallium nitride instead of silicon, which has been commonly used in existing power devices.

“They cannot operate at high voltages,” Lostetter said.

But devices built using silicon carbide can operate at high voltages. Usually, electricity must pass through a transformer to reduce its voltage; however, with the Wolfspeed devices, the voltage would not need to be stepped down, allowing the electricity to “come straight off the line,” Lostetter said. “It’s a game changer.”

Transformers are heavy and are wound with copper wire, which is expensive, and eliminating them from the charging system would reduce weight and cost.

“The transformers today are thousands of pounds,” Lostetter said.

Wolfspeed’s complete fast charging system would weigh less than 770 pounds, compared to an equivalent existing system, which weigh more than 5,500 pounds or nearly 3 tons. Also, changing the voltage leads to power loss, and power loss causes heat. The proposed device would operate at cooler temperatures.

PROJECT SCOPE

Wolfspeed will use silicon carbide in the project, which is expected to take three years to complete, Lostetter said. A rendering of the charging device should be completed in six months. The device is expected to be used for commercial purposes, and might be sold to a third party. The prototype will be created by Wolfspeed, but the large-scale production of the charging devices will be completed by a manufacturer.

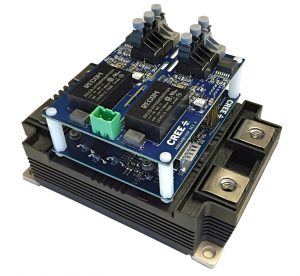

The technology — the semiconductors and modules — that will operate the charging devices have been developed, so the project will encompass designing and building the device. “We have the semiconductor technology,” he said. “It’s the power switch — the switching of voltage and current.”

Wolfspeed builds the semiconductors at its location in Research Triangle Park, N.C., and the modules, which are comprised of a group of the semiconductors, are created at its 30,000-square-foot facility at Arkansas Research & Technology Park in Fayetteville.

“We’re always expanding,” he said.

Over the next four to six months, it will add 5,000 square feet to make room for growth, some of which is related to development of the modules. Between both locations, Wolfspeed has about 610 employees, with 60 employees working in Fayetteville. It has eight to 10 open positions for engineers and manufacturing positions. The company will continue to manufacture the semiconductors and modules, even if the charging device is sold to a third party and is manufactured by another company.

Wolfspeed has yet to implement the semiconductor technology for commercial use, but outside of this project, it’s being tested for various applications, such as for power grids. It’s working with the U.S. military to help improve efficiencies in electricity demand for Navy warships, which are consuming about 10 times the power that they used to require, Lostetter said.

However, the technology still has its challenges before it can be used commercially and has to be proven reliable for the long-term. A timeline for when it will be used commercially has not been set.

Cree, a public company founded in 1987, has built its business around developing semiconductor switches, Lostetter said. In 2015, Cree purchased Fayetteville-based APEI, when Lostetter was its president and CEO.

On Aug. 22, Cree reported its fiscal year 2017 revenue fell 9% to $1.47 billion and saw a net loss $98.11 million, or a loss of $1 per share. In the year that ended June 25, Wolfspeed accounted for 17% or $60.83 million of Cree’s revenue, up 30% from fiscal 2016.

ELECTRIC FUTURE

Wolfspeed is partnering with Ford Motor Co. to test the fast-charging device for real-world applications. How the device will work with an electric vehicle is part of the project, and some parts of the charging device might be equipped on the vehicle itself, depending on how it’s designed.

Some of the drawbacks of electric vehicles compared to a traditional internal combustion engine vehicle are their limited range and their ability to quickly recharge the batteries.

Bret Jordan, equity analyst for Jefferies, expects internal combustion engine vehicles to “remain the core propulsion technology for at least the next two decades.” By 2025, electric vehicles will comprise of less than 5% of vehicles in use globally, “given range and battery cost limitations.”

Globally, 0.2% of passenger vehicles in use are electric vehicles, according to the International Energy Agency. In 2016, the number of electric vehicles doubled to 2 million, from 2015.

“Headwinds to greater near-term [electric vehicle] penetration include battery capacity, ‘range anxiety,’ lack of charging infrastructure, demand dependence on government subsidies and relative affordability,” Jordan noted. “While we expect [electric vehicle] manufacturers to make headway in improving battery capacity and production costs in the longer term, current economics and improving forced induction and hybrid efficiency favors [internal combustion engine vehicles] remaining the core propulsion technology.”

Other headwinds for electric vehicles include the improved fuel efficiency of internal combustion vehicles, low gas prices and ample supply of crude oil globally. In 2014, the average fuel efficiency for a new passenger car rose to 36.4 mpg, from 28 mpg in 1990.

But the excitement surrounding electric vehicles has been on the rise recently with the launch of the Tesla Model 3 and LG’s plans to build an electric vehicle power components facility in Detroit, according to equity analyst David Kelly of Jefferies.